Life Science Leader is always thankful for having so many executives and thought leaders taking part and contributing to our annual outlook issue (published in December). That said, sometimes we can’t squeeze in all the great insights shared within the print pages of just one publication. When such happens, we turn to our online exclusive section — Beyond The Printed Page. Here you’ll find 100 articles from biopharmaceutical industry thought leaders sharing opinions on a variety of diverse topics. For this installment, we have six biopharmaceutical industry manufacturing executives sharing their perspectives toward helping their peers prepare for 2021 and beyond.

WHAT’S GOING TO BE BIG IN BIOPHARMA MANUFACTURING IN 2021 (AND BEYOND) THAT WAS SPARKED BY THE PANDEMIC?

MARGARET OLINGER, CCO, AMYLYX

The pandemic is a bold reminder of the importance of global manufacturing duplication so that we can avoid disruptions. Whether that is procuring raw materials from multiple places around the world, or creating manufacturing capabilities in different geographic locations, “redundancy” is the key word for 2021 and beyond. Every biopharma company must look at its ability to serve patients without interruption. It’s essential that our backup plans for supply, manufacturing, and distribution, work toward ensuring people who can benefit from our medications will receive them. While this is particularly important during a pandemic, people rely on our industry, and we have to create multiple ways to serve those in need.

WHAT ARE SOME OF THE BIGGEST CHALLENGES TO BE OVERCOME IN THE NEXT FEW YEARS FOR PERSONALIZED BIOPHARMA MANUFACTURING TO BECOME COMMONPLACE?

TOVE’ C. BOLKEN, SVP OPERATIONS & CHIEF SUPPLY CHAIN OFFICER, SIGA TECHNOLOGIES

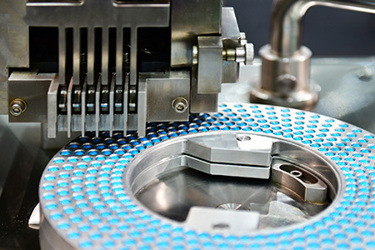

To put the patient first and truly personalize medicine, there needs to be a push for infrastructure improvements in biologic manufacturing. This could include flexible GMP facilities, new cell culture techniques, improved purification processes, and other strategies that overcome the complexities, costs, and lead-times of biologic manufacturing. Also, bringing more manufacturers into this space would provide more capacity and the competition necessary to facilitate a drive for excellence. A lot of personalized medicine relies on biologics, and there are a limited number of manufacturers capable of producing these sterile complex biologic drugs in the United States. The increased costs of producing these personalized drugs may make them difficult for many to be able afford. This must be combatted by increased volume driven by physician feedback, diagnostic data, and genetic testing to support the effectiveness of that personalized medicine.

RUTUL SHAH, HEAD OF OPERATIONS AND PORTFOLIO, PRECIGEN

The biggest challenges for the broad applicability of cell therapies, which are at the forefront of personalized medicine, are high cost of treatment and the long delays in vein-to-vein time, rendering them unsuitable for patients with rapidly progressing disease. Today’s cell therapies are manufactured at centralized high-tech facilities that require multifaceted and logistically complex supply chains. While limitations and potential bottlenecks in these supply chains have been a challenge since these technologies were first adopted, the COVID-19 pandemic has highlighted how a slow down or work stoppage at even one point along the supply chain can significantly disrupt the manufacture of these products. The magnitude of this challenge may become even more significant when manufacturing supply chains rely on one or more third-party vendors or CMOs, each of which may be subject to their own supply chain disruptions. Developing streamlined and localized manufacturing processes that allow cell therapies to be produced close to or in the care centers where they are administered to patients will help to reduce complexity and manufacturing timelines that can delay treatment.

WHAT EMERGING INNOVATIONS WILL IMPACT BIOPHARMA MANUFACTURING WITHIN THE NEXT FIVE YEARS THAT FEW ARE PAYING ATTENTION TO?

DAVID KNOP, VP PROCESS DEVELOPMENT, AGTC

Focusing again on the gene therapy space, there needs to be greater emphasis on innovating technologies and systems that allow manufacturing productivity intensification. With more traditional biologics, suspension bioreactors can allow continuous manufacturing from cell cultures maintained for months in a productive state. In contrast, the production of viral vectors for gene therapy is a terminal process in which the generation and release of vector particles typically leads to the death of the producer cells. Process intensification would permit significant reduction in cost of goods, with or without commensurate scaling, and will continue to be critical for addressing disease indications with large populations, like macular degeneration, or those that require large doses of vector to achieve therapeutic benefit, like the muscular dystrophies.

JOE NEWELL, COO, ATARA BIOTHERAPEUTICS

One area my team often discusses is our collective ability to move away from the traditional use of cell markers to define cell characteristics. Additional investment in single cell genome and expression analytical tools would allow us to advance the level of precision that is going to be expected as cell therapy matures. Another major component that would have a big impact is moving away from traditional viral vectors and into an alternate technology to perform cell modifications. Perhaps the biggest opportunity in the allogeneic cell therapy space is the ability to scale up manufacturing processes. There has been a great deal of energy and investment into process throughput, but I think our ability to scale up our process requires equal focus. Technology and equipment managers are working on the issue, but there is an opportunity here across the industry.

ARE THERE DISRUPTIVE TECHNOLOGIES BEYOND AI AND MACHINE LEARNING THAT WILL TRANSFORM BIOPHARMA MANUFACTURING IN THE NEXT THREE TO FIVE YEARS?

CHRISTOPHER MURRAY, PH.D., SVP TECHNICAL OPERATIONS, BLUEPRINT MEDICINES

Over the next several years and beyond, I anticipate continuous manufacturing will become more accessible and common in the biopharma industry. As context, biopharma companies have traditionally conducted batch-based manufacturing, with each product batch produced at a single, uniform dose. This approach has not evolved significantly over the last several decades. Today, companies are increasingly exploring continuous manufacturing processes that involve making tablets, for example, through a long running (nearly) continuous manner, potentially providing benefits in process control and better economics. In addition, individualized doses of a product may one day become commonplace. This approach offers the promise of bringing us closer to addressing the specific needs of each individual patient, advancing on the potential of precision medicine. For example, patients may need precisely tailored dosing based on their body weight or other individual characteristics. Equipment advancements and other breakthroughs are enabling continuous manufacturing to achieve high levels of control, supporting product safety, and addressing important regulatory requirements. In addition, this approach reduces the space requirements needed to manufacture, as it enables the use of dedicated, small-footprint equipment to make each product, offering the potential for increased efficiency and cost savings.

WHAT CURRENT GOVERNMENT POLICY, PROPOSED OR ALREADY ENACTED, DO YOU ANTICIPATE HAVING THE MOST SIGNIFICANT IMPACT ON BIOPHARMA MANUFACTURING IN 2021 AND BEYOND?

JOE NEWELL, COO, ATARA BIOTHERAPEUTICS

I think the most impactful government policy may be the recent (written September 2020) Executive Order that the President recently issued. It is aimed at setting up Medicare demonstration projects in Part B and Part D that would assess the feasibility and impact of requiring U.S. Medicare to receive most-favored nation pricing among comparable OECD (Organisation for Economic Co-operation and Development) countries. It is important to note that biologic products are in scope. Although it is unclear what the immediate impact will be, I think it is fair to state that pricing will eventually come under significant pressure. As such, the costs associated with biomanufacturing will as well. For the biomanufacturing community, the spotlight needs to remain focused on productivity and the ability to manufacture quality products at a competitive cost of goods manufactured (COGM). This will likely trigger investments to ensure process improvements that help lower COGM are included earlier in the development cycle. As an industry we have made progress in this regard over the last decade. However, those that adapt early and double down on these efforts will have the best chance to maintain competitive margins.

RUTUL SHAH, HEAD OF OPERATIONS AND PORTFOLIO, PRECIGEN

Recent FDA guidance on gene and cell therapy manufacturing has been helpful in establishing expectations for manufacturers of these therapies. But they assume that gene and cell therapies will be manufactured in central-processing facilities. As we move toward point of care therapies that utilized modified autologous cells that may be manufactured in hospitals or care centers, there will be new challenges to regulating quality, purity, and potency. Again, recent global events have made it clear that geographically distributed supply chains are subject to disruption on multiple fronts, including public health issues; transportation challenges due to fires, floods, or other weather events; or global trade considerations. Furthermore, processing of autologous cells can require several weeks before patients can be treated. Manufacturing at the point of care has significant benefits that may improve access to these therapies. The regulatory landscape isn’t evolving as quickly as the technology landscape enabling this approach. This needs to be addressed before it becomes a bottleneck to further technological evolution needed for making cell therapies the standard of care.

WHAT IS YOUR OPINION AS TO HOW A U.S. RESHORING OF BIOPHARMA MANUFACTURING CAPABILITIES WILL IMPACT THE U.S. AND GLOBAL BIOPHARMACEUTICAL INDUSTRIES?

MARGARET OLINGER, CCO, AMYLYX

We live in strange times that reinforce the need to think locally and act globally. Laws change in every country, and we need to adapt so that we can continue to serve people who are in need. Talent is not limited to one geography, and our ability to obtain raw materials and manufacture must be done in multiple locations so we do not experience interruptions. Regardless of the U.S. political climate, we should focus on how to best serve patients, and that often means manufacturing in multiple countries.

GIVEN THE ANTICIPATED RESHORING OF AMERICAN BIOPHARMA MANUFACTURING, DO YOU ANTICIPATE A SHIFT THAT COULD TAKE SHAPE IN “CLUSTERS?”

TOVE’ C. BOLKEN, SVP OPERATIONS & CHIEF SUPPLY CHAIN OFFICER, SIGA TECHNOLOGIES

For reshoring to be successful, existing U.S. manufacturers of raw materials and APIs need to be incentivized to make the material in the U.S., along with some amount of certainty that other companies are going to buy from them, as opposed to their existing foreign source. Setting up partnerships and supply agreements would help provide that certainty. A lot of work has to go into reducing production costs and equipping the U.S. sites with the special chemical processes and equipment required to make these materials. Without these key drivers, the prices of drugs will go up, and patients will bear the financial burden for reshoring biopharmaceutical manufacturing.

The first subset to target is the manufacturing of raw materials and APIs, and then we can expand into the manufacturing of finished drug product. Raw materials and APIs require a large factory site, the ability to handle environmental liabilities, and access to a low-cost labor force. This means that reshoring of American biopharmaceutical manufacturing will not happen in clusters, but be driven by government incentives and crucial partnerships, leveraging existing manufacturing sites across the U.S. and in states that encourage, and perhaps incentivize, the building of new manufacturing facilities.

DAVID KNOP, VP PROCESS DEVELOPMENT, AGTC

Several factors will ultimately determine whether there’s a manufacturing parallel to the R&D clusters. Despite the COVID-19 pandemic radically altering the workplace, most manufacturing positions require an on-site presence, and have returned to, or did not pause, on-site activities. Do we need to have lots of people clustered in one area to be effective? Not necessarily. But it often makes attracting talent easier if high-value hires don’t have to relocate or a critical mass of technology has accumulated in a hub. Tax incentives will play a significant role. Many states realize that biopharma manufacturing facilities provide high-quality jobs that offer good pay and benefits and can help to revitalize, maintain, and grow their economies.

Currently, North Carolina appears to be one of the most aggressively expanding hubs for gene therapy manufacturing. Both Pfizer and Novartis/AveXis have gene therapy manufacturing facilities there, and Beam Therapeutics announced in August 2020 that it will build an $83 million manufacturing facility there — creating hundreds of jobs. As such, gene and cell therapy manufacturing clustering may already be taking place.

Source: Life Science Leader